YLM Heavy Industry Ciencia y Tecnología duranteel proceso de desarrollo de los últimos 30 años, se fuerma una cultura empresarial y rica en contenido único.

La construcción de la cultura de la empresa YLM Heavy Industry Ciencia y Tecnología ser la cohesión y la solidaridad del punto de agregación y la fuente de energía para el desarrollo sostenible de las empresas.

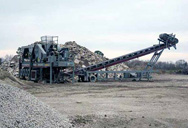

Charlar en LíneaSe trata de una moderna empresa con la investigación, fabricación y ventas juntos. La matriz se encuentra enla zona HI-TECH Industry Development de Zhengzhou y cubiertas 80.000 m ².

YLM Heavy Industry

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Address:No.169, Science (Kexue) Avenue, National HI-TECH Industry Development Zone, Zhengzhou, China

Send E-mail:[email protected]

The purpose of this activity was to determine the characteristics of gold contained in iron sand mining tailings based on mineragraphic parameters, gold recovery by amalgamation method, and Hg used and wasted with tailings in the amalgamation

Bavarder sur Internet

Individual layers of deposited tailings are composed of mixtures of tailings sand (particles larger than 63 m) and tailings slimes (particles smaller than 63 m). The sands are shown

Bavarder sur Internet

DRD Gold, one of the first South African companies to abandon traditional mining to focus on extracting gold from tailings. New technology allows it to recover up to 40% of the gold left in...

Bavarder sur Internet

The research of gold processing from tailings of iron sand processing from South Kalimantan by using amalgamation methods in West Java November 2019

Bavarder sur Internet

in which p 0 = 1 kPa; e 0 = initial void ratio corresponding to p 0; and C c = compression index. The fitting results of the four tailings are summarized in Table 2.The compression

Bavarder sur Internet

The gold mining process involves crushing the ore into sand and dust to liberate and recover the gold. What’s leftover is called tailings. Ballarat Gold Mine uses

Bavarder sur Internet

The gold content in gold mine tailings is generally 0.2-0.6g/t. Due to the backward mining technology in the past, some of the gold and silver is lost in the tailings. At the same time, most of the gold ore in

Bavarder sur Internet

Gold mine tailings Tailings are one of the primary waste products of mining operations. They are made of fine grained particles of the parent rock from which the ore is

Bavarder sur Internet

166K views 1 year ago Smelting and refining gold ore tailings to determine how much gold is still locked up. By smelting the material down and performing a large assay the

Bavarder sur Internet

The water retentivity of cement mortar with gold mine tailings and river sand is 88.3% and 77% respectively. The water retentivity increases as the fineness of

Bavarder sur Internet

Amalgamation is a gold metal extraction method that is more suitable for ore in the form of pure gold free or free gold with high gold content and has a coarse particle size or greater than 74 microns. The amalgamation process is carried out by mixing gold ore with mercury to form an Hg-Au alloy. Basically, amalgamation is a sika chemical

Bavarder sur Internet

sandy soils and classified as silty sand (SM) by the Unified Soil Classification System, while the gold tailings were sandy silt (ML) and the coal wash tailings were clayey silts (CL). Bussière (2007) provides a summary of the ‘hydrogeotechnical’ properties of tailings. This work indicated that samples from nine different Canadian hard ...

Bavarder sur Internet

A representative sample of gold mine wastes of sandy grain size was used in making the glass. Based on composition, the glass was formulated by adding an average 10.0 mass% of CaCO3 and 5.0 mass ...

Bavarder sur Internet

The gold mining process involves crushing the ore into sand and dust to liberate and recover the gold. What’s leftover is called tailings. Ballarat Gold Mine uses its robust management and monitoring processes to make sure its produced gold tailings comply with all license conditions and permits necessary for the safe storage of tailings.

Bavarder sur Internet

Oil sands tailings are a mixture of water, sand, fine silts, clay, residual bitumen and lighter hydrocarbons, inorganic salts and water-soluble organic compounds. Tailings are stored in basins called tailings ponds, which allow the solids in tailings to settle. The sand component of tailings settles out quickly, leaving the clay and silt to ...

Bavarder sur Internet

Smelting and refining gold ore tailings to determine how much gold is still locked up. By smelting the material down and performing a large assay the amount...

Bavarder sur Internet

5. Reclamation. Land reclamation is also an effective way to treat gold mine tailings. Certain measures are taken on the gold mine tailings pond to plant agricultural, forestry, animal husbandry, and vital

Bavarder sur Internet

use is to make ceramics made from gold mining waste tailings of P.T. Freeport-Timika. Physically, the tailings composition consists of a 50% fine sand fraction with a diameter of 0.075 – 0.4 mm; the

Bavarder sur Internet

gold eand traction from sand tailings Basic Smallworking Gold Eand Traction Process and registrationlicensing fees can the ground is just the first step for gold ore eand traction Live Chat eand traction process flow chart in mines the techniques of eand traction of gold from ore iron ore process of eand traction equipment A flowchart is a . ...

Bavarder sur Internet

Gold Eand Traction From Sand Tailings. gold extraction from sand tailings. How To Extract Gold From Sand? Mining pedia. In gold sand gravity separation, when roughing with a chute or jig, the coarse concentrate is usually enriched by a shaker with a very high ore ratio, its recovery rate can reach more than 98%, and directly get the

Bavarder sur Internet

Hydrofluoric Acid Flotation Method. The hydrofluoric acid method is a commonly used method for recycling quartz sand from gold tailings. The process involves using hydrofluoric acid to dissolve ...

Bavarder sur Internet

The type of tailings dam a mining company builds is directly related to the safety of the structure. Engineers have found that tailings dams tend to be safest, i.e. most resistant to failure and collapse, when they are not built on top of or using previously-deposited tailings.However, the safest dams, like downstream dams, are more expensive to

Bavarder sur Internet

Typically, mill tailings range from sand to silt-clay in particle size. Ore is material that contains a mineral commodity of value required to sustain modern life. Mineral commodities commonly recovered in the United States are copper, gold, silver, iron,

Bavarder sur Internet

In contrast, the cement-to-tailings ratio considerably affected the wear rate at a higher flow rate. The mechanism of the solid particles in the slurry acting on the test block is the same as that on the pipe wall. The traction load particles' move along the inner wall of the pipeline is the main form of motion leading to pipeline wear.

Bavarder sur Internet

The nickel and gold tailings are typically comprised of fine waste from materials mined in greenstone belts. Where ‘fresh rock’ is mined from underground deposits or deep pits, the material will typically have a relatively higher SG than the waste from an ‘oxide ore’ stream.

Bavarder sur Internet

A representative sample of gold mine wastes of sandy grain size was used in making the glass. Based on composition, the glass was formulated by adding an average 10.0 mass% of CaCO3 and 5.0 mass ...

Bavarder sur Internet

Oil sands tailings are a mixture of water, sand, fine silts, clay, residual bitumen and lighter hydrocarbons, inorganic salts and water-soluble organic compounds. Tailings are stored in basins called tailings ponds, which allow the solids in tailings to settle. The sand component of tailings settles out quickly, leaving the clay and silt to ...

Bavarder sur Internet

Tailings management in gold-silver mining, on the other hand, is important from both harmful effects and eyesore standpoint of huge amount process tailings containing cyanide and/or cyanide -metal ...

Bavarder sur Internet

Gold tailings, also known as gold mine tailings, are the residue left over from the process of extracting gold from ore. The tailings usually contain a large amount of quartz sand,...

Bavarder sur Internet

166K views 1 year ago Smelting and refining gold ore tailings to determine how much gold is still locked up. By smelting the material down and performing a large assay the

Bavarder sur Internet

5. Reclamation. Land reclamation is also an effective way to treat gold mine tailings. Certain measures are taken on the gold mine tailings pond to plant agricultural, forestry, animal husbandry, and vital

Bavarder sur Internet

gold eand traction from sand tailings Basic Smallworking Gold Eand Traction Process and registrationlicensing fees can the ground is just the first step for gold ore eand traction Live Chat eand traction process flow chart in mines the techniques of eand traction of gold from ore iron ore process of eand traction equipment A flowchart is a . ...

Bavarder sur Internet

Gold Eand Traction From Sand Tailings. gold extraction from sand tailings. How To Extract Gold From Sand? Mining pedia. In gold sand gravity separation, when roughing with a chute or jig, the coarse concentrate is usually enriched by a shaker with a very high ore ratio, its recovery rate can reach more than 98%, and directly get the

Bavarder sur Internet

Tailings are the waste materials left after the target mineral is extracted from ore. They consist of: Crushed rock Water Trace quantities of metals such as copper, mercury, cadmium, zinc, etc. Additives used in

Bavarder sur Internet

For rough calculations in the absence of definite data, it is usual to allow 8-12 sq. ft. of settling area per ton of dry tailing per 24 hours. The underflow should contain no more water than is needed to make it

Bavarder sur Internet

In contrast, the cement-to-tailings ratio considerably affected the wear rate at a higher flow rate. The mechanism of the solid particles in the slurry acting on the test block is the same as that on the pipe wall. The traction load particles' move along the inner wall of the pipeline is the main form of motion leading to pipeline wear.

Bavarder sur Internet

Typically, mill tailings range from sand to silt-clay in particle size. Ore is material that contains a mineral commodity of value required to sustain modern life. Mineral commodities commonly recovered in the United States are copper, gold, silver, iron,

Bavarder sur Internet

gold eand traction in taif saudi arabia. equipment used for iron ore eand traction in tanzania. finding gold ore in saudi arabia. p15 jan 2014 gold eand traction in taif saudi arabia more details gold mining stamp machines in south africagold eand traction in riyadh saudi arabia 2011 china equipment used for iron ore eand traction in tanzania more

Bavarder sur Internet