YLM Heavy Industry Ciencia y Tecnología duranteel proceso de desarrollo de los últimos 30 años, se fuerma una cultura empresarial y rica en contenido único.

La construcción de la cultura de la empresa YLM Heavy Industry Ciencia y Tecnología ser la cohesión y la solidaridad del punto de agregación y la fuente de energía para el desarrollo sostenible de las empresas.

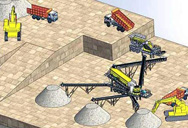

Charlar en LíneaSe trata de una moderna empresa con la investigación, fabricación y ventas juntos. La matriz se encuentra enla zona HI-TECH Industry Development de Zhengzhou y cubiertas 80.000 m ².

YLM Heavy Industry

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Address:No.169, Science (Kexue) Avenue, National HI-TECH Industry Development Zone, Zhengzhou, China

Send E-mail:[email protected]

In principle, steelmaking is a melting, purifying, and alloying process carried out at approximately 1,600° C (2,900° F) in molten conditions. Various chemical reactions are

Bavarder sur Internet

Details the process of steel production, including relevant chemical reactions and how various furnaces work. KEYWORDS (Audience): General Public KEYWORDS (Feature):

Bavarder sur Internet

During the steelmaking process, fluxes that consist of lime (CaO) or dolomitic lime, with iron and scraps, are charged to the furnace. There is a certain amount of free lime (f-CaO) in

Bavarder sur Internet

Steelmaking is a process of selective oxidation of impurities, which is the reverse of ironmaking. In principle, it is similar to the fire refining of nonferrous metals but the end

Bavarder sur Internet

Chemistry of Steelmaking by Basic Oxygen Steelmaking Basic oxygen steelmaking (BOS) is the most widely used primary steelmaking process for the production of crude steel from hot metal

Bavarder sur Internet

This book presents the fundamentals of iron and steel making, including the physical chemistry, thermodynamics and key concepts, while also discussing associated

Bavarder sur Internet

1 Physical Chemistry of Steelmaking. Steelmaking is an oxidation process in which the impurities in the hot metal are oxidized by lancing oxygen into the

Bavarder sur Internet

Metallurgy: An Introduction to the Physical Chemistry of Iron and Steel Making. R. G. Ward. Arnold, London; St. Martin's Press, New York, 1962. ix + 238 pp. Illus. Science Home

Bavarder sur Internet

The Physical Chemistry of Steelmaking; The Physical Chemistry of Steelmaking Proceedings of the Conference The Physical Chemistry of Iron and

Bavarder sur Internet

Iron and steelmaking process is energy intensive. Generally speaking, energy constitutes a significant portion of production cost, from 20% to 40%, according to the estimation from world steel association [7]. About 95% of energy for an integrated steelmaking plant comes from solid fuel (mainly coal), 3–4% from gaseous fuel and 1–2% from ...

Bavarder sur Internet

steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). By far the most widely used material for building the world’s

Bavarder sur Internet

Electric-arc steelmaking. About one-quarter of the world’s steel is produced by the electric-arc method, which uses high-current electric arcs to melt steel scrap and convert it into liquid steel of a specified chemical composition and temperature. External arc heating permits better thermal control than does the basic oxygen process, in which heating is

Bavarder sur Internet

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter process is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel.Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel.The process is

Bavarder sur Internet

Steelmaking is an oxidation process in which the impurities in the hot metal are oxidized by lancing oxygen into the bath. The products of oxidation like oxides, silicates, phosphates and sulphides are taken by the slag, and the carbon is oxidized to carbon monoxide and goes out as gas.

Bavarder sur Internet

Ladle metallurgy. The carrying out of metallurgical reactions in the ladle is a common practice in practically all steelmaking shops, because it is cost-efficient to operate the primary furnace as a high-speed melter and to

Bavarder sur Internet

Metallurgy: An Introduction to the Physical Chemistry of Iron and Steel Making. R. G. Ward. Arnold, London; St. Martin's Press, New York, 1962. ix + 238 pp. Illus. Science Home Science Vol. 139, No. 3558 Metallurgy: An Introduction to the Physical Chemistry of Iron and Steel Making. R. G. Ward.

Bavarder sur Internet

The Physical Chemistry of Steelmaking; The Physical Chemistry of Steelmaking Proceedings of the Conference The Physical Chemistry of Iron and Steelmaking Endicott House, Dedham, Massachusetts 28 May to 3 June, 1956. Edited by John F. Elliott. $40.00 Paperback; Hardcover; 252 pp., 9 x 11 in,

Bavarder sur Internet

The first stage involves getting a semi-product in primary steel making process furnace such as converter, electric arc furnace or induction furnace, whereas the second stage consists in refining of steel in the secondary steelmaking process such as ladle refining furnace, or vacuum degassing furnace.

Bavarder sur Internet

Slags, steelmaking chemical information summary. Slags, steelmaking chemical information summary. National Institutes of Health. National Library of Medicine. National Center for Biotechnology Information ... Chemical reaction regulator. Filler. Fillers. Intermediate. Intermediates. Other. Other (specify) Processing aids not otherwise specified.

Bavarder sur Internet

Details the process of steel production, including relevant chemical reactions and how various furnaces work.

Bavarder sur Internet

chemistry of steelmaking in Chapter 2. Further, they discovered that sufficient heat was generated in the vessel by the chemical oxidation of the above elements in most types of pig iron to permit the simple blow-ing of cold air through molten pig iron to produce liquid steel without the need for an

Bavarder sur Internet

During the basic oxygen process (BOP), oxygen blown into a combination of molten pig iron and scrap metal refines the product into steel. Some steelmakers blow oxygen from the top onto the surface of the melt, in a basic oxygen furnace.

Bavarder sur Internet

Primary steelmaking has two methods: BOS (Basic Oxygen Furnace) and the more modern EAF (Electric Arc Furnace) methods. The BOS method adds recycled scrap steel to the molten iron in a converter. At high temperatures, oxygen is blown through the metal, which reduces the carbon content to between 0-1.5%.

Bavarder sur Internet

Details the process of steel production, including relevant chemical reactions and how various furnaces work.

Bavarder sur Internet

steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). By far the most widely used material for building the world’s

Bavarder sur Internet

During the steelmaking process, fluxes that consist of lime (CaO) or dolomitic lime, with iron and scraps, are charged to the furnace. There is a certain amount of free lime (f-CaO) in steel slag.

Bavarder sur Internet

Electric-arc steelmaking. About one-quarter of the world’s steel is produced by the electric-arc method, which uses high-current electric arcs to melt steel scrap and convert it into liquid steel of a specified chemical composition and temperature. External arc heating permits better thermal control than does the basic oxygen process, in which heating is

Bavarder sur Internet

Ladle metallurgy. The carrying out of metallurgical reactions in the ladle is a common practice in practically all steelmaking shops, because it is cost-efficient to operate the primary furnace as a high-speed melter and to

Bavarder sur Internet

The basic oxygen steel-making process is as follows: Molten pig iron (sometimes referred to as "hot metal") from a blast furnace is poured into a large refractory-lined container called a ladle. The metal in the ladle is sent directly for basic oxygen steelmaking or to a pretreatment stage.

Bavarder sur Internet

Steelmaking is an oxidation process in which the impurities in the hot metal are oxidized by lancing oxygen into the bath. The products of oxidation like oxides, silicates, phosphates and sulphides are taken by the slag, and the carbon is oxidized to carbon monoxide and goes out as gas.

Bavarder sur Internet

chemistry of steelmaking in Chapter 2. Further, they discovered that sufficient heat was generated in the vessel by the chemical oxidation of the above elements in most types of pig iron to permit the simple blow-ing of cold air through molten pig iron to produce liquid steel without the need for an

Bavarder sur Internet

The Physical Chemistry of Steelmaking; The Physical Chemistry of Steelmaking Proceedings of the Conference The Physical Chemistry of Iron and Steelmaking Endicott House, Dedham, Massachusetts 28 May to 3 June, 1956. Edited by John F. Elliott. $40.00 Paperback; Hardcover; 252 pp., 9 x 11 in,

Bavarder sur Internet

Slags, steelmaking chemical information summary. Slags, steelmaking chemical information summary. National Institutes of Health. National Library of Medicine. National Center for Biotechnology Information ... Chemical reaction regulator. Filler. Fillers. Intermediate. Intermediates. Other. Other (specify) Processing aids not otherwise specified.

Bavarder sur Internet

Metal ores are generally oxides, sulfides, silicates (Table 12.3.1) or "native" metals (such as native copper) that are not commonly concentrated in the Earth's crust, or "noble" metals (not usually forming compounds) such as gold (Figure 12.3.1 ). The ores must be processed to extract the metals of interest from the waste rock and from

Bavarder sur Internet

Steelmaking is the second step in producing steel from iron ore. In this stage, impurities such as sulfur, phosphorus, and excess carbon are removed from the raw iron, and alloying elements such as manganese, nickel, chromium, and vanadium are added to produce the exact steel required.

Bavarder sur Internet

Electric Arc Furnace Steelmaking By Jeremy A. T. Jones, Nupro Corporation Courtesy of Mannesmann Demag Corp. ... Chemical energy is be supplied via several sources including oxy-fuel burners and oxygen lances. Oxy-fuel burners burn natural gas using oxygen or a blend of oxygen and air. Heat is transferred to the scrap by flame radiation and ...

Bavarder sur Internet

A new route for making steel from iron ore based on the use of hydrogen to reduce iron oxides is presented, detailed and analyzed. The main advantage of this steelmaking route is the dramatic ...

Bavarder sur Internet